Why Marine Electrical Work Requires Specialized Contractors in Augusta

Marine electrical contractors in augusta ga provide specialized electrical services for boats, docks, and waterfront properties along the Savannah River and surrounding waterways. Unlike standard residential electricians, these contractors must understand saltwater corrosion, marine safety codes, and waterproof installation techniques.

Marine electrical work presents unique challenges that regular electricians aren’t equipped to handle. Saltwater environments cause rapid corrosion of standard wiring and components. Boats constantly move and vibrate, requiring flexible connections and marine-grade materials.

The electrical systems on watercraft must also meet strict Coast Guard and ABYC (American Boat and Yacht Council) safety standards. These codes differ significantly from residential electrical work – requiring specialized knowledge of galvanic isolation, shore power connections, and fire suppression systems.

Qualified marine electrical contractors specialize in installation and service of onboard wiring for motors, pumps, fixtures, and other equipment necessary for marinas. Professional marine electrical services include comprehensive electrical solutions with emergency support capabilities.

I’m Jesse Burnett, Master Electrician and founder of Dr. Electric CSRA, with over 1,200 completed electrical projects across residential, commercial, and industrial settings. While I primarily focus on land-based electrical work, I understand the critical importance of connecting Augusta boat owners with qualified marine electrical contractors in augusta ga who have the specialized training and certifications needed for safe watercraft electrical systems.

Marine electrical contractors in augusta ga word guide:

– augusta ga commercial electrical contractors

– electrical rewiring augusta ga

– landscape lighting augusta ga

Top 7 Must-Have Qualities When Choosing Marine Electrical Contractors in Augusta GA

Finding the right marine electrical contractors in augusta ga can feel overwhelming, but focusing on these seven essential qualities will help you make the best choice for your waterfront electrical needs.

ABYC certification should be your first checkpoint. The American Boat and Yacht Council sets the safety standards that keep boats from becoming floating fire hazards. Certified contractors understand the critical differences between land and water electrical work – like proper grounding techniques and galvanic isolation that prevent your boat’s metal parts from dissolving away.

24/7 emergency response capability isn’t just a nice-to-have feature when you’re dealing with marine electrical systems. Storms don’t wait for Monday morning, and neither do electrical failures at the dock. You need contractors who can respond immediately when your shore power goes out or your boat’s electrical system fails during a weekend trip.

Experience with corrosion-resistant materials separates true marine specialists from regular electricians. Standard copper wire turns green and crumbles in saltwater environments. Professional marine contractors use tinned copper wire, stainless steel fasteners, and sealed connections that actually survive Georgia’s humid waterfront conditions year after year.

Marina shore power and surge protection expertise becomes crucial when you’re plugging your expensive boat into dock power. Proper surge protection and load distribution prevent costly damage to your boat’s electronics. The wrong setup can fry everything from your GPS to your refrigeration system in seconds.

Battery bank design and solar integration knowledge reflects today’s marine electrical reality. Modern boats run complex battery systems with lithium banks, solar panels, and inverters. Your contractor needs to understand how these systems work together safely and efficiently.

Local waterway permit experience can save you months of bureaucratic headaches. Georgia’s waterways have specific regulations for dock construction and electrical installations. Contractors familiar with local permitting requirements can steer the approval process smoothly while you focus on enjoying your boat.

Comprehensive insurance and liability coverage protects both you and the contractor when working around water and expensive equipment. Marine electrical work carries significant risks, and proper coverage ensures you’re not left holding the bill if something goes wrong.

Certification Checklist for Marine Electrical Contractors in Augusta GA

Before signing any contract, verify your chosen contractor holds ABYC Marine Electrical Certification and a Georgia State Electrical License. USCG Safety Training and OSHA 30-Hour Marine Safety Certification demonstrate additional commitment to safe practices around water.

Insurance requirements include general liability coverage of at least $1 million, plus professional liability and workers’ compensation insurance. Marine-specific coverage for watercraft work provides extra protection for your valuable boat.

Look for manufacturer certifications for specific equipment brands, ongoing continuing education in marine electrical codes, and a portfolio of local marina references. Emergency response capabilities with clear contact information round out the essential qualifications.

Common Projects Handled by Marine Electrical Contractors in Augusta GA

Marine electrical contractors in augusta ga tackle everything from basic dock lighting to complex boat electrical systems. Shore power pedestal installation and upgrades form the backbone of marina infrastructure, providing safe, weatherproof connections for multiple boats.

Navigation light retrofits and LED conversions improve visibility and reduce power consumption, while bilge pump circuits with automatic switching protect boats from flooding. Battery charging systems and inverter installations keep modern boats powered and comfortable at anchor.

Safety and compliance upgrades include GFCI and AFCI protection device installation, galvanic isolator systems to prevent corrosion, and fire suppression system electrical connections. Emergency lighting and alarm systems provide critical safety backup when regular power fails.

The complexity of marine electrical work requires specialized knowledge that goes far beyond standard residential wiring. Proper installation and long-term reliability in harsh marine environments depend on contractors who understand these unique challenges and have the experience to handle them safely.

How Marine Electrical Work Differs from Land-Based Jobs

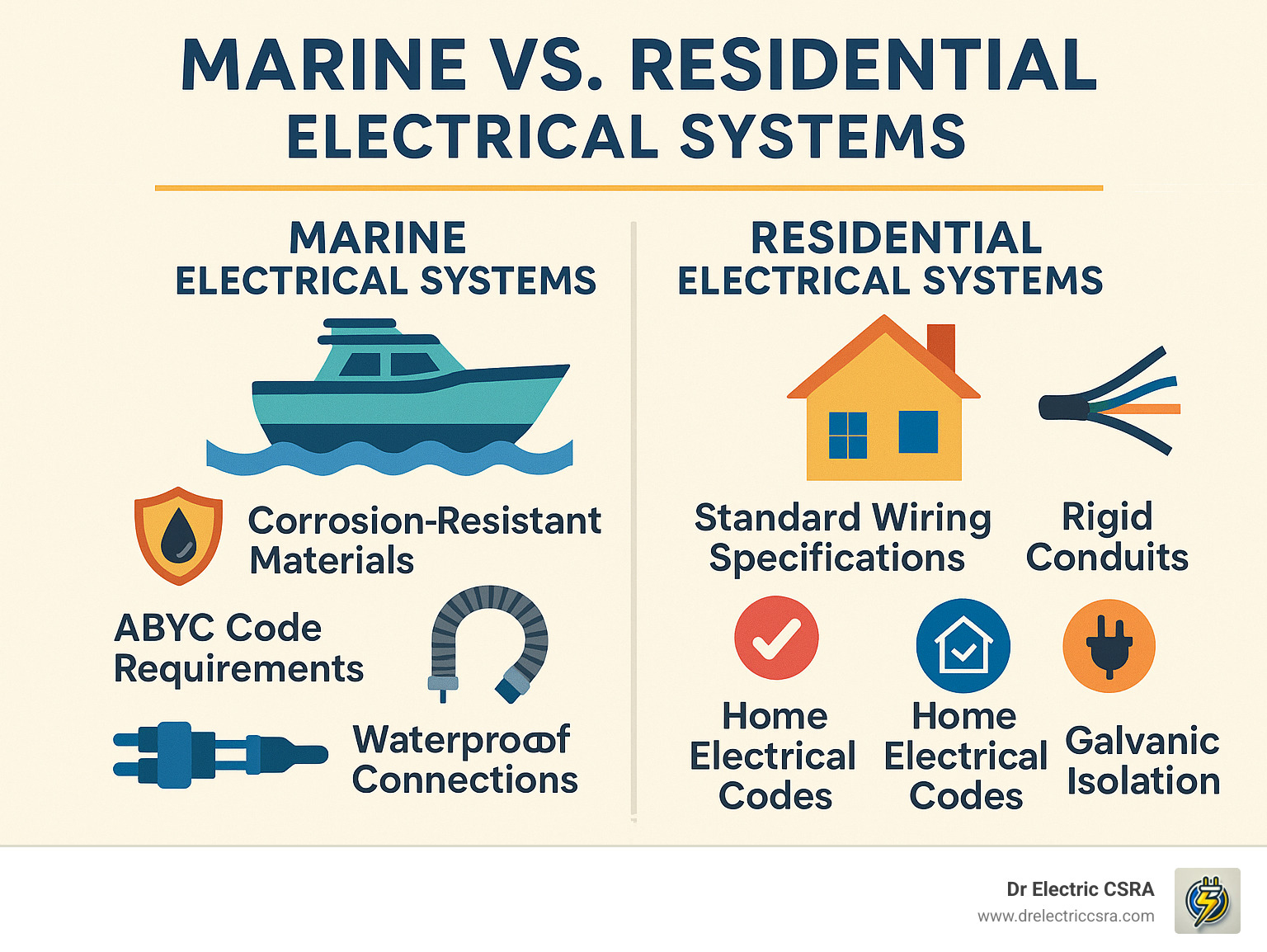

Working on boats and docks isn’t just regular electrical work with a waterproof twist. The differences between marine and residential electrical systems are so significant that marine electrical contractors in augusta ga need completely different training, materials, and techniques.

The Saltwater Enemy

Saltwater is like kryptonite to electrical systems. While your home’s copper wiring might last decades, regular copper wire in a marine environment will turn green with corrosion and fail within months. That’s why marine contractors must use tinned copper conductors – copper wire coated with tin to resist corrosion.

The hardware tells the same story. Standard galvanized screws and brackets that work fine in your house will rust away quickly near water. Marine electrical work requires stainless steel fasteners and specialized protective coatings to survive the harsh environment.

When Your Boat Becomes a Battery

Here’s something that doesn’t happen in your living room: galvanic corrosion. When different metals on your boat touch the water while connected to shore power, they can create an unwanted electrical current. This turns your expensive boat into a giant battery that literally eats itself from the inside out.

Marine electrical systems need galvanic isolators or isolation transformers to prevent this destructive process. It’s a concept that simply doesn’t exist in residential work, but it’s absolutely critical for protecting your investment on the water.

Everything Moves on a Boat

Your house sits still, but boats are constantly moving with waves, wake, and weather. Every electrical connection must flex and bend without breaking or coming loose. Marine contractors use flexible conduits and specialized strain reliefs that can handle this constant motion.

The terminations and connections are completely different too. Standard wire nuts and rigid connections that work perfectly in your attic will fail quickly on a moving vessel. Marine electrical work requires vibration-proof terminals and flexible connection methods.

Explosion Prevention

Boat engine compartments contain fuel vapors that can ignite from the smallest electrical spark. Marine electrical equipment must meet strict ignition protection standards using sealed components and proper ventilation. These safety requirements are far more demanding than anything in residential electrical work.

Every switch, outlet, and connection in areas where fuel vapors might collect needs special ignition-protected devices. It’s not just about following code – it’s about preventing potentially deadly explosions.

The Bottom Line Differences

| Marine Electrical | Residential Electrical |

|---|---|

| Tinned copper wire | Standard copper wire |

| Stainless steel hardware | Galvanized/standard hardware |

| Flexible conduits | Rigid conduits |

| Ignition-protected devices | Standard switches/outlets |

| ABYC code compliance | NEC code compliance |

| Galvanic isolation required | No isolation needed |

| Waterproof connections | Weather-resistant connections |

| Vibration-resistant terminations | Standard terminations |

These aren’t just minor variations – they’re fundamental differences that require specialized knowledge and experience. That’s why choosing qualified marine electrical contractors makes such a difference in the safety and reliability of your watercraft electrical systems.

Safety Codes & Compliance on Georgia Waters

When it comes to marine electrical work on Georgia’s waterways, safety isn’t just important – it’s literally a matter of life and death. Marine electrical contractors in augusta ga must steer a complex web of safety codes and regulations that exist for one simple reason: to keep boaters safe from electrocution, fires, and other electrical hazards.

Think of these codes as layers of protection, each one designed to catch what the others might miss. It’s like wearing both a belt and suspenders – maybe it seems like overkill, but when you’re dealing with electricity and water, there’s no such thing as being too careful.

The National Electrical Code Takes the Lead

NEC Article 555 serves as the foundation for all marina and boatyard electrical work. This isn’t your typical residential electrical code – it’s specifically written for the unique challenges of waterfront environments. The code mandates GFCI protection for all marina outlets because even a small electrical fault near water can be deadly.

The spacing requirements in Article 555 might seem picky, but they’re based on decades of accident investigations. Electrical equipment must be positioned where it won’t get splashed by waves or damaged by boat movement. Every measurement has a purpose.

ABYC Standards Keep Boats Safe

The American Boat and Yacht Council doesn’t mess around when it comes to safety. ABYC Standards E-11 and E-9 cover both AC and DC electrical systems on boats, specifying everything from proper wire sizing to circuit protection methods.

These standards recognize that boats aren’t houses – they move, they get wet, and they operate in an environment where a small electrical problem can quickly become a big emergency. The installation methods required by ABYC standards account for constant vibration, moisture exposure, and the need for quick repairs in remote locations.

Georgia’s Environmental Rules Matter Too

The Georgia Environmental Protection Division (EPD) adds another layer of requirements that focus on protecting our waterways. When marine electrical contractors in augusta ga install electrical systems, they must obtain proper permits and follow environmental protection guidelines.

These rules ensure that electrical installations don’t harm fish habitats or water quality. It’s not just about making the electrical system work – it’s about making sure it works without damaging the environment that makes boating so enjoyable.

Fire Safety Integration

Here’s where things get really technical. Marine electrical systems must integrate seamlessly with fire suppression equipment, maintaining proper spacing and avoiding any interference with safety systems. In engine compartments where fuel vapors can accumulate, electrical components need special ignition protection ratings.

This integration requires contractors who understand both electrical systems and fire safety principles. A poorly placed electrical component could actually make a fire worse instead of better.

Modern Protection Requirements

Today’s marine electrical installations require both GFCI and AFCI protection in many situations. Ground Fault Circuit Interrupters prevent electrocution, while Arc Fault Circuit Interrupters prevent electrical fires caused by damaged wiring or loose connections.

These protection devices are especially important in marine environments where wiring can be damaged by vibration, corrosion, or physical impact. They act as electronic guardians, constantly monitoring the electrical system and shutting off power the instant they detect danger.

The science behind marine electrical safety continues to evolve. Scientific research on corrosion control helps contractors stay current with the latest developments in preventing galvanic corrosion and extending system life in saltwater environments.

At Dr Electric CSRA, while we focus on land-based electrical work, we deeply respect the specialized knowledge required for marine electrical systems. The complexity of these safety codes demonstrates why boat owners need contractors who live and breathe marine electrical work every day.

Step-by-Step Process to Hire and Keep Your Marine Electrical Team

Hiring the right marine electrical contractors in augusta ga doesn’t have to feel overwhelming. Think of it like finding a good doctor – you want someone qualified, trustworthy, and available when you need them most.

Start with detailed quotes from multiple contractors. The best marine electricians will ask lots of questions about your boat, dock, or marina before giving you a price. They might even want to see your setup in person. If someone gives you a quote over the phone without asking specifics, that’s a red flag.

Schedule a thorough inspection next. A qualified contractor will document everything with photos and give you a written report. They’re not just looking at what’s broken – they’re spotting potential problems before they leave you stranded at the dock.

The scope proposal is where everything gets official. This detailed document spells out exactly what work will be done, which materials will be used, and how long it’ll take. Don’t skip this step – it protects both you and the contractor from misunderstandings later.

Permits might seem like a hassle, but they’re crucial. Marine electrical work often requires approval from local authorities and marina management. Experienced contractors handle this paperwork dance so you don’t have to. They know which forms to file and which inspectors to call.

During installation, watch for contractors who keep things clean and organized. Quality professionals protect your boat and workspace while following ABYC standards. They use marine-grade materials that can handle saltwater and constant movement.

Load testing happens after everything’s wired up. This isn’t just flipping switches to see if lights turn on. Proper testing verifies that circuits can handle their intended loads, GFCI devices work correctly, and grounding systems provide safety protection.

Don’t forget about ongoing maintenance. Marine electrical systems need regular attention to prevent expensive failures. Work with your contractor to set up inspection schedules and maintenance routines. While we handle maintenance services for land-based electrical systems, marine systems require specialized ongoing care from qualified marine contractors.

Budget & Pricing Guidelines

Marine electrical work costs more than regular house wiring, but understanding typical rates helps you spot fair deals and avoid lowball scams.

Hourly rates for basic marine electrical work typically run $85 to $125 per hour. More complex installations might cost $100 to $150 per hour. Emergency calls after hours? Expect $150 to $200 per hour – but that’s still cheaper than being stuck without power during a storm.

Project packages vary widely based on complexity. A simple shore power pedestal installation might cost $800 to $1,500, while a complete boat electrical system upgrade can run $5,000 to $15,000 or more. Marina electrical distribution projects often start at $10,000 and can reach $50,000 for large facilities.

Emergency service usually costs 1.5 to 2 times normal rates. Building a relationship with a contractor beforehand might reduce these surcharges when you really need help.

Seasonal timing affects pricing too. Spring and early summer are busy seasons when everyone’s getting their boats ready. Planning major projects for fall or winter can save you 10 to 20 percent.

Working With Other Marine Professionals

Marine electrical contractors rarely work alone. The best projects happen when different specialists coordinate their efforts smoothly.

Marine mechanical technicians handle engines, pumps, and other moving parts that need electrical connections. Good contractors communicate well with mechanics to ensure everything works together properly.

HVAC and refrigeration installers depend on electrical contractors for power and control circuits. Modern boats need sophisticated climate control, and the electrical work must be done right to support these systems.

Marine surveyors document system conditions for insurance and financing. Electrical contractors often work with surveyors to ensure installations meet insurance requirements and safety standards.

Marina and boatyard managers coordinate multiple contractors and enforce facility standards. Building good relationships with marina management makes projects run smoother and faster.

The marine service industry continues evolving toward more integrated approaches, with contractors collaborating closely to provide comprehensive solutions. For broader insights into boat service trends, the focus remains on quality, safety, and customer satisfaction.

Frequently Asked Questions about Augusta Marine Electrical Work

Marine electrical work can feel overwhelming, especially when you’re dealing with the unique challenges of waterfront properties and boats. Let me address the most common questions we hear from Augusta boat owners and marina operators.

What qualifications should a contractor show before working on my boat?

Your boat represents a significant investment, and the wrong electrical work can be dangerous or costly. Marine electrical contractors in augusta ga should provide clear proof of their qualifications before you hire them.

The most critical certification is ABYC Marine Electrical Certification. This proves the contractor understands marine-specific safety codes, corrosion prevention, and proper installation techniques. Without this certification, they’re essentially guessing about marine electrical requirements.

You’ll also want to see a valid Georgia electrical license and proof of liability insurance with at least $1 million coverage. Workers’ compensation coverage protects you if someone gets injured on your property.

Ask to see their portfolio of similar marine projects and get references from local marinas or boat owners. Experienced contractors will gladly share examples of their work and put you in touch with satisfied customers.

Professional contractors provide written estimates with detailed scope of work, use proper marine-grade tools and equipment, and understand local permitting requirements. They should also give you emergency contact information and explain their response capabilities.

Never hire contractors who can’t provide these credentials. The marine environment is too dangerous for unqualified electrical work, and your insurance may not cover damage caused by unlicensed contractors.

How quickly can emergency dock power be restored after a storm?

Storm damage to marine electrical systems can leave you stranded or without essential power. Response times depend on several factors, but here’s what you can typically expect.

Most qualified contractors can provide initial assessment within 2-4 hours during business hours. Basic emergency repairs often take 4-8 hours, while complex system restoration may require 1-3 days depending on the extent of damage.

Parts availability can extend timelines by 1-2 additional days. Marine electrical components aren’t always in stock locally, especially specialized items like galvanic isolators or marine-grade panels.

Research shows that some marine contractors offer 24-hour on-call service for urgent system failures, which represents the gold standard for emergency response in the marine electrical industry.

Several factors affect response times: the severity and extent of damage, weather conditions that might prevent safe work, the number of simultaneous emergency calls, and the complexity of your electrical systems.

You can prepare for emergencies by establishing relationships with contractors before you need them, keeping emergency contact information readily available, and documenting your electrical systems with photos and diagrams. Consider backup power options for critical systems like bilge pumps.

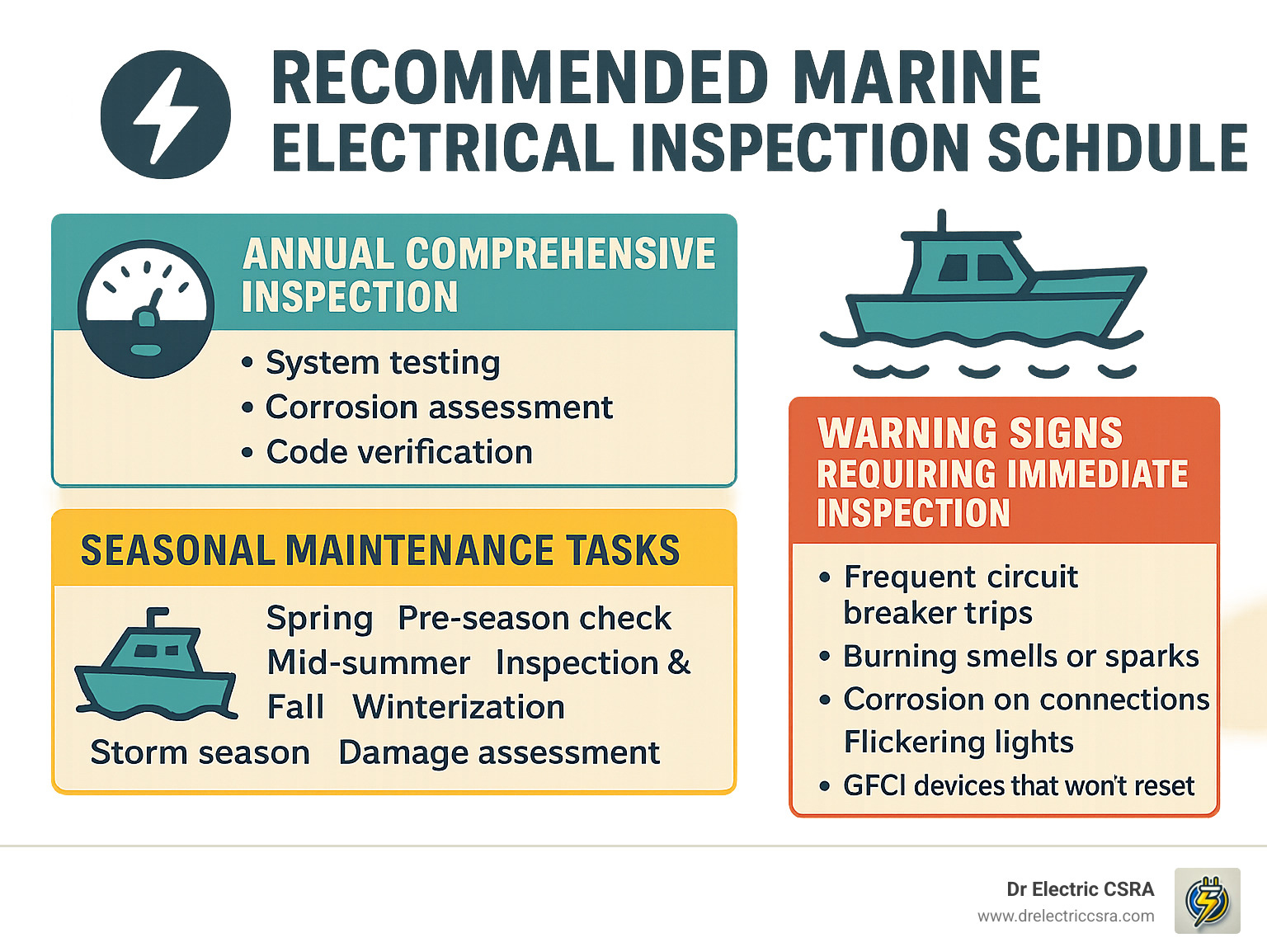

How often should I schedule preventive electrical inspections?

Regular inspections prevent costly failures and keep you safe on the water. The marine environment is particularly harsh on electrical systems, so consistent maintenance is essential.

Schedule a comprehensive annual inspection that includes complete system testing, corrosion assessment, code compliance verification, and safety equipment testing. This thorough checkup catches problems before they become expensive emergencies.

Seasonal maintenance checks keep your systems running smoothly. In spring, activate and test systems before heavy use. Mid-summer inspections during peak season help identify wear and clean connections. Fall maintenance includes winterization and system protection. After storm season, assess any weather-related damage.

High-use systems need more frequent attention. Check battery systems monthly for proper voltage and clean connections. Inspect shore power connections weekly for signs of wear or corrosion. Test navigation lights and bilge pump circuits monthly to ensure they’ll work when needed.

Some warning signs require immediate inspection: frequent circuit breaker trips, burning smells or visible sparks, corrosion on electrical connections, flickering lights or intermittent power, and GFCI devices that won’t reset.

Regular maintenance might seem like an expense, but it’s much cheaper than emergency repairs or replacing damaged equipment. Plus, well-maintained electrical systems are safer and more reliable when you’re out on the water.

Conclusion

Finding the right marine electrical contractors in augusta ga isn’t just about getting the lights to work on your boat. It’s about protecting your family, your investment, and ensuring you can enjoy Georgia’s beautiful waterways without worry.

The marine electrical world is completely different from regular house wiring. Saltwater doesn’t forgive shortcuts, and boats present unique challenges that require specialized knowledge. From understanding galvanic corrosion to properly installing ignition-protected equipment, these contractors need skills that go way beyond what most electricians learn.

Local expertise makes all the difference when you’re dealing with Georgia’s waterways and regulations. Contractors who understand our local permitting requirements, know the marinas along the Savannah River, and can respond quickly during storm season provide peace of mind you can’t get from just anyone with a toolbox.

Safety always comes first in marine electrical work. The combination of water, electricity, and fuel vapors creates serious risks that demand respect. Proper ABYC certification isn’t just a nice-to-have credential – it’s essential knowledge that prevents fires, electrocution, and expensive equipment damage.

Code compliance protects your investment in ways you might not realize. Insurance companies pay attention to who did your electrical work, and they expect proper certifications and permits. Taking shortcuts now often leads to coverage denials later when you need help most.

The 24/7 emergency response capability we’ve discussed throughout this guide isn’t just convenient – it’s often critical. Electrical failures don’t wait for Monday morning, and having a trusted contractor’s number saved in your phone can save your weekend (and your wallet).

Regular maintenance keeps small problems from becoming big headaches. Just like you wouldn’t skip oil changes on your car, marine electrical systems need consistent attention to handle the harsh environment they work in every day.

Here at Dr. Electric CSRA, we focus on keeping the lights on and systems running safely in homes and businesses throughout Augusta, Evans, Grovetown, and Martinez. While we specialize in land-based electrical work, we deeply respect the specialized skills that marine electrical work requires.

Your electrical safety matters everywhere – whether you’re flipping a switch at home or starting your boat engine. The same attention to detail, code compliance, and safety standards should guide all your electrical decisions.

When you need help with your home or business electrical systems, we’re here with the same commitment to quality and safety that you should expect from marine contractors. Our contact options are always available, and we understand that electrical problems don’t keep regular hours.

Remember: specialized work requires specialized experts. Whether it’s complex commercial wiring or marine electrical systems, the right contractor makes all the difference between a job done right and a problem waiting to happen.

Stay safe out there on Georgia’s waters, and don’t hesitate to reach out when you need reliable electrical service back on dry land.

0 Comments